«

»

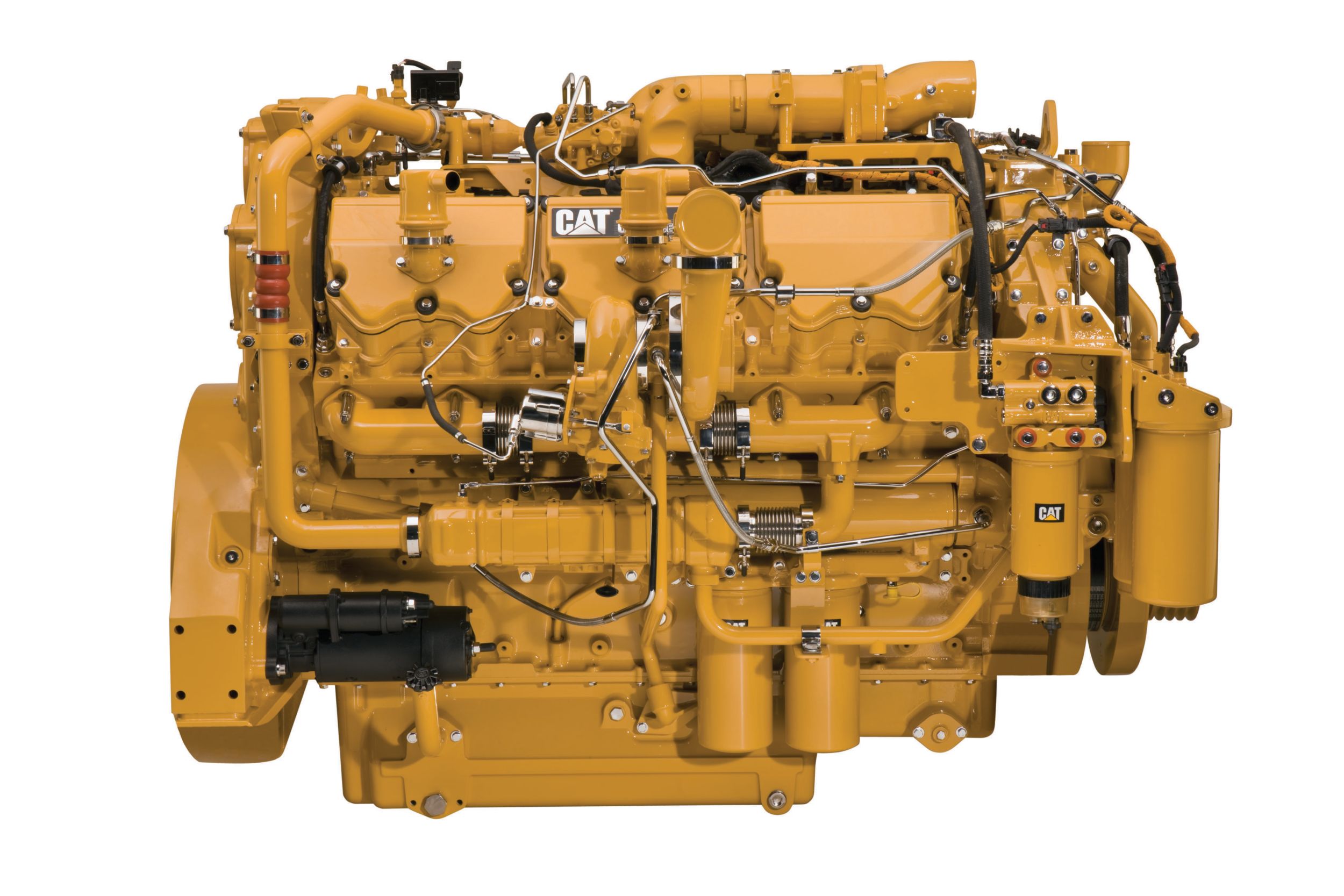

Maximum Rating

1050 BHP

|

Emissions U.S. EPA Non-road Tier 4 Final |

Displacement

1648 in³

|

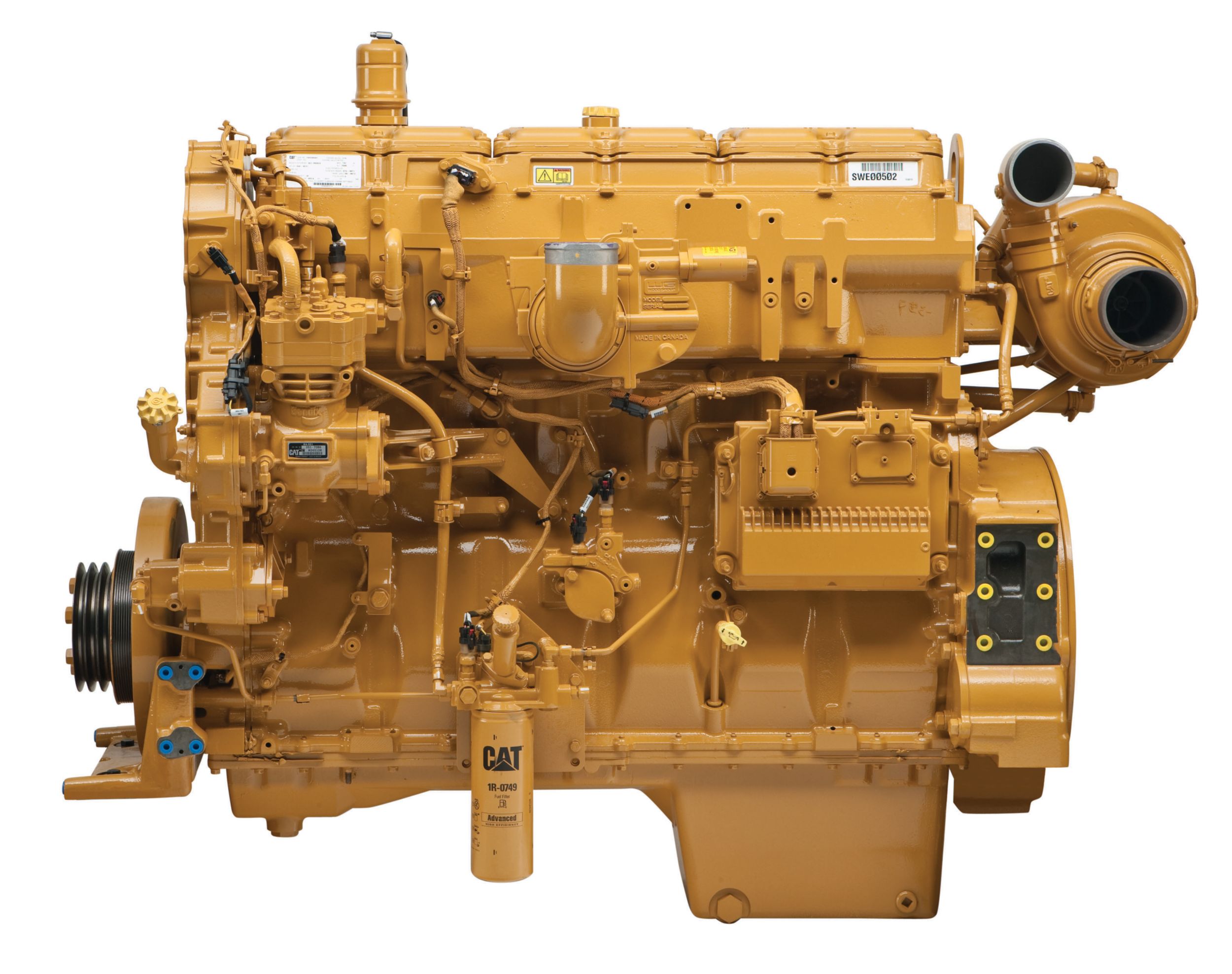

Minimum Rating

440 BHP

|

Maximum Rating

595 BHP

|

Emissions EPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA |

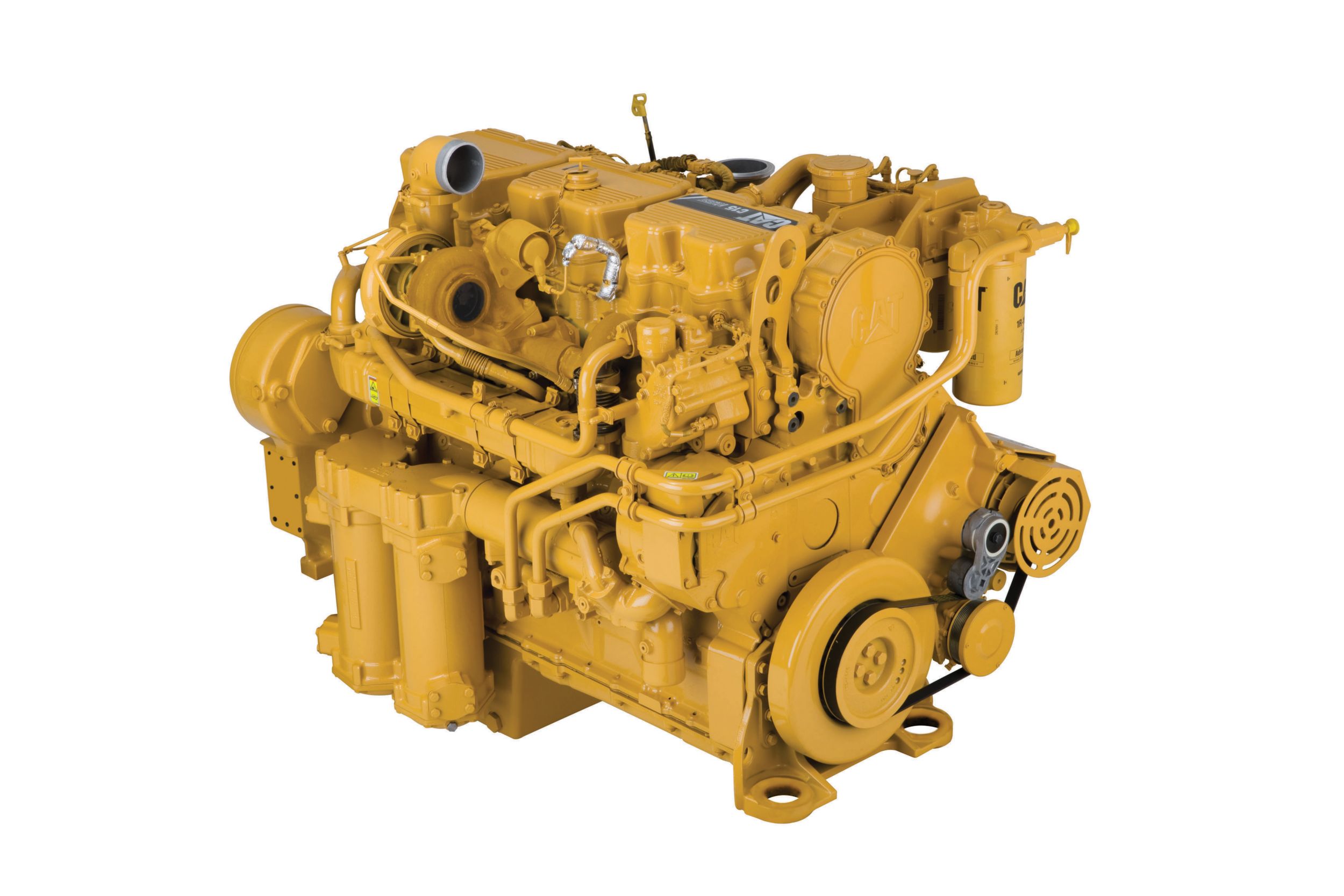

Minimum Rating

475 BHP

|

Emissions U.S. EPA Tier 4 Final, EU Stage V |

Maximum Rating

581 BHP

|

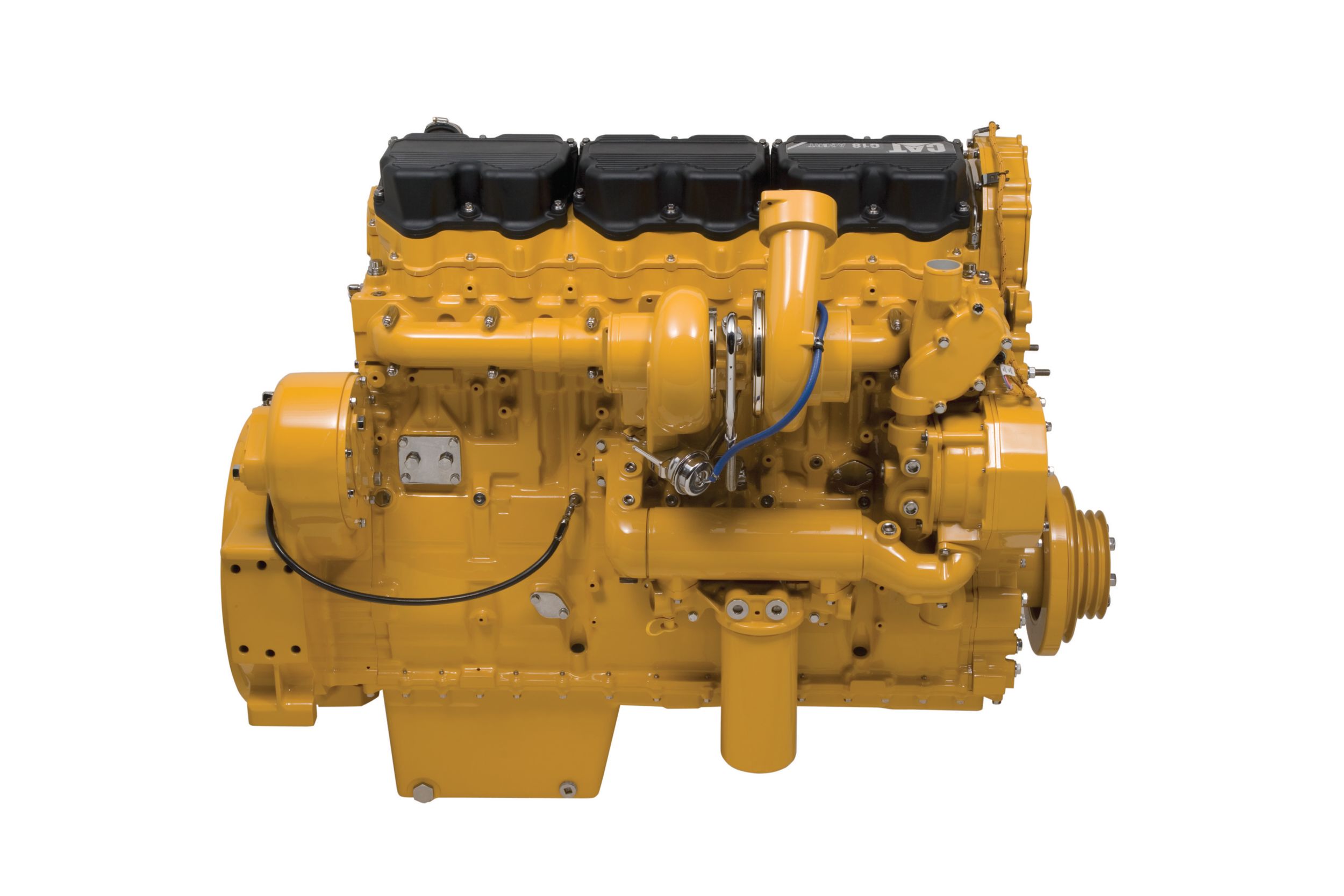

Maximum Rating

700 BHP

|

Emissions EPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA |

Displacement

1100 in³

|